Over the last number of years, several models have been developed that are now all grouped under the one heading, PIGLAB.

These models are in various states of development, some are fully coded as usable computer programs, others are spreadsheets and still others are manual calculations. These models are used in-house to provide services for clients.

Philosophy

Verification of the models is ongoing and extensive. When used in specialist pig design, the philosophy has been:

Use the tools to compare various pig designs, focusing in on the one most likely to work over the whole pipeline. When this is achieved, vary some of the more estimated parameters (eg Youngs Modulus) to make sure the pig still works over a range of inputs. This is similar to the approach adopted by engineers designing a pipeline. In this respect, PIGLAB is similar to performing tests on pigs using a loop to develop the optimal configuration. However, many more scenarios can be evaluated quickly and cost-effectively.

MATLAB and Simulink

Pipeline Research Limited’s future aim is to code all these models using MATLAB and Simulink, into four tools that can be used to aid pig design processes.

Modules

The various modules include:

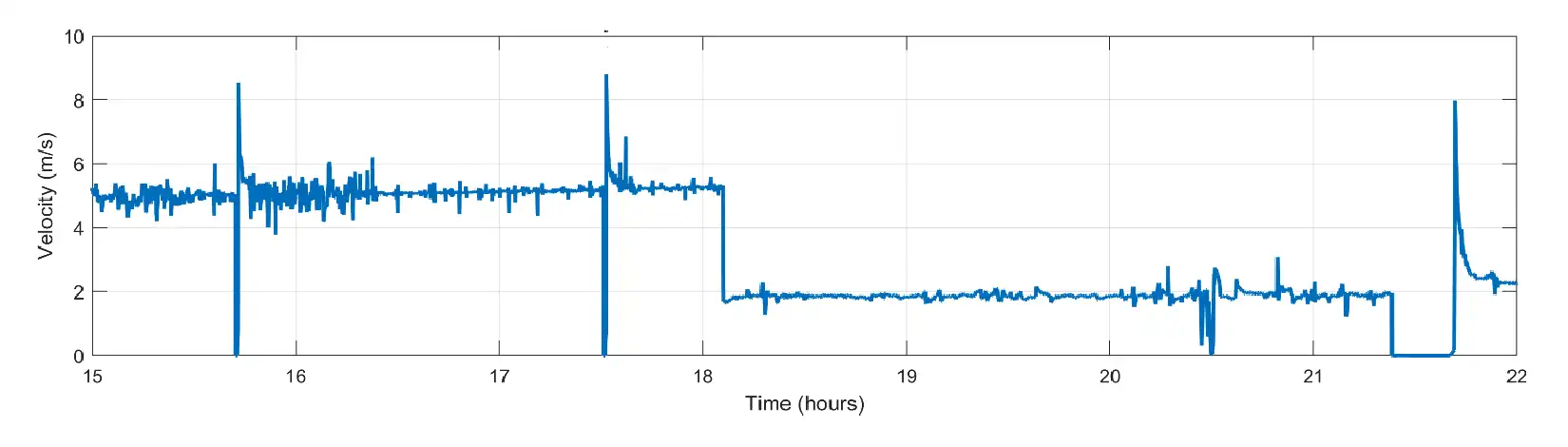

- PIGLAB – Compressible, for determining pig velocity in gas pipelines;

- PIGLAB – Precomm, for-estimating pig velocity and pressure requirements during pipeline pre-commissioning;

- PIGLAB – Two Phase, for evaluation of pig velocity and liquid hold up in two phase lines (Under development);

- PIGLAB – Wear and Lubrication, to examine the effects of distance and velocity on the behaviour of the pig in terms of differential pressure, wear and leakage.